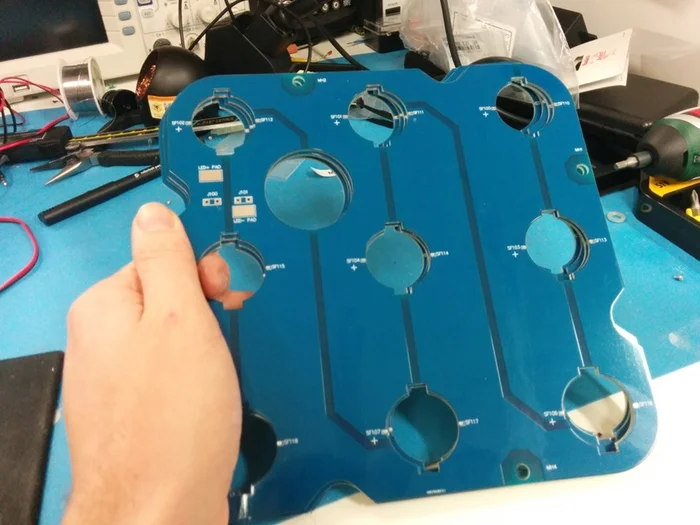

Yesterday I spent the day at the factory where the electronics are being manufactured, and where final assembly is taking place. In my last update I said that final assembly should have been taking place last week. Her Majesty's Revenue and Customs have unfortunately prevented that so far, with the metalwork currently sitting in a warehouse in Southampton Docks waiting for customs clearance. However the time isn't being wasted, and most of the rest of the parts are now complete.

The end is in sight!

In a few short days the first complete Vela One flashes should be coming off the production lines. Here's an update on where everything is now.

The Vela One is made of several main parts, and these are all being made in different factories around the world. They are all descending over the next week on a factory in the South of England for final assembly.

Manufacturing update

Vela One: now in production!

This is it: manufacture has started! The Chinese are back from holiday and it’s all go. Last week we made the first payment to our metalwork factory, so this week they start building. I’m really pleased to say that things are still almost on schedule (not too much shifting has been needed in my Great Gantt of Doom™) and we’re still within the margin of error that I built into the plans.

To manufacture!

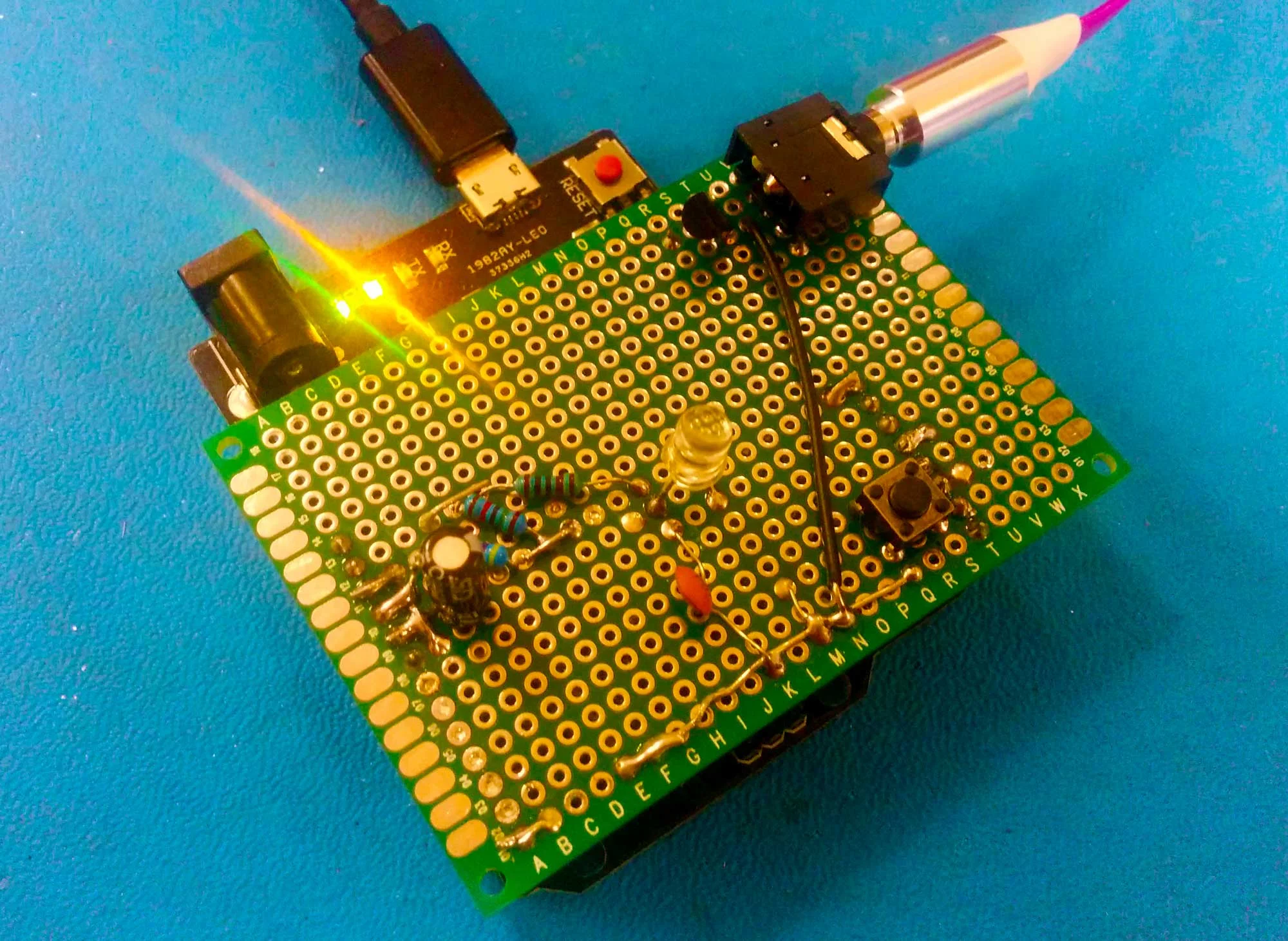

How fast is your flash - using high-speed timers and interrupts with Arduino

I’ve built a low cost, high-speed timer for camera flashes as an Arduino shield. As well as being useful for photographers, this has been an interesting exercise in using high speed, accurate AVR timers, interrupts and input capture on Arduino. Excluding the Arduino itself, the total cost came to around $3.

Give me all the photons!

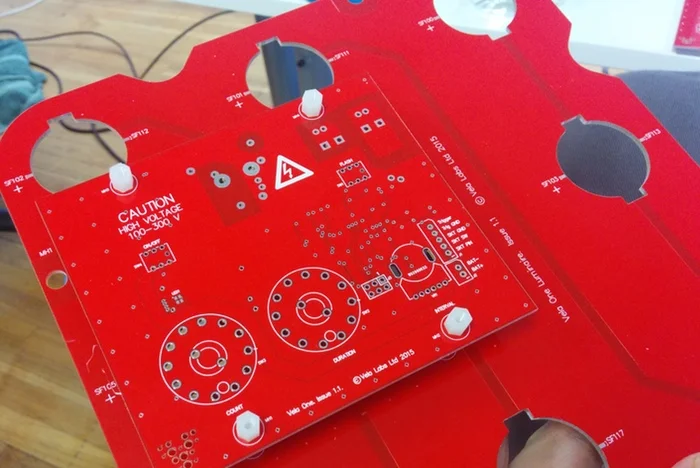

Hello all! In an earlier update I mentioned that I'd shown in testing that we were having problems with parasitic inductance, which was meaning the rise time was much longer than in earlier tests. Essentially what this means is that it was taking a long time (around 2-3us) to get to peak brightness, which meant that we were missing out on a lot of light. I knew that this was solvable, as the earlier prototypes didn't suffer from this problem. I've spent the last few weeks working on a new luminaire design (the bit that holds the LEDs, reflectors etc), as this seemed to be the source of the problem. The new boards arrived last week, and I'm happy to say that they do solve the problem! As well as fixing the inductance issue, the boards are also simpler, lighter and much quicker to assemble.

In the studio and ready to go

Nearly there! More than a year since I first had the idea to create a new kind of high-speed flash, and six months since I started working on it full time, it’s almost time to unveil the Vela flash to the world. It has been a week since the final enclosure prototypes arrived, since which I’ve been flat out taking product photos and filming the Kickstarter video. The really fun bit though has been doing a proper round of testing in the studio. This time I graduated from my studio in a box to use my office meeting room. I was lucky enough to get hold of one of the final production prototypes of the Triggertrap Ada sound trigger. Rich Harley, Triggertrap’s Head of Product, brought it over to Vela Labs and we spent a day running comprehensive tests on both of them.